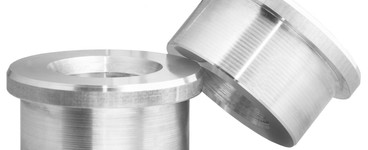

Straight Bushings

When it comes to heavy equipment and industrial machinery, degradation is commonplace.

From extreme temperatures to corrosive conditions, the oil and gas industry regularly operates in harsh at-sea and onshore environments. The equipment used to explore, drill, extract, refine, and transport the energy that powers societies must stand up to the stress.

Enhance your oil and gas application performance with U.S. Bronze Foundry & Machine. Our oil and gas casted metal parts withstand wear and degradation, keeping equipment operating efficiently for extended periods.

U.S. Bronze Foundry & Machine is a single-source supplier of oil and gas casted metal parts. We manufacture items that optimize functionality and wearability, lowering operating costs.

When it comes to heavy equipment and industrial machinery, degradation is commonplace.

As heavy materials pass through minerals processing equipment, components begin to wear.

Without nuts to hold things together, heavy equipment would fall apart.

Gears are toothed, mechanical transmission elements used to transfer motion and power between components.

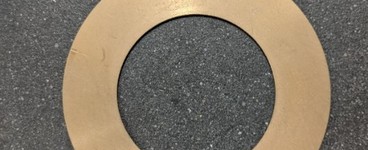

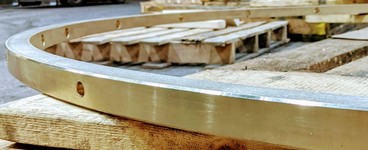

Cast rings are found all around us, from jet engines to military equipment.

Heavy equipment and machines are essential for completing industrial functions on time and within budget.

Heavy equipment success and failure sometimes comes down to the ability to withstand loads repeatedly.

Whether lifting substantial loads or crushing hard minerals, heavy machinery must tolerate extreme forces repeatedly.

In industrial applications, pumps and compressors are relied upon to power critical devices.

Unmitigated friction can bring any industrial application to a halt. Protect heavy equipment against wear with tapered bushings from U.S. Bronze Foundry & Machine.

Mining and materials-handling operators often must reduce raw material sizes to create something sellable.

When it comes to heavy machinery, unaddressed friction can be catastrophic.

The ability to withstand loads repeatedly is critical for heavy machinery. Boost equipment performance with flange bushings from U.S. Bronze Foundry & Machine.

Sometimes, being unbalanced better. Take your application to new performance levels with eccentric bushings from U.S. Bronze Foundry & Machine.

Every casting step is performed in-house under the direction of qualified engineers. Our capabilities include:

The oil and gas industry uses metal castings when high levels of durability, friction-resistance, and anti-corrosion capabilities are needed. Here are common oil and gas casted metal parts:

A diverse array of oil and gas applications utilize metal castings, from drilling equipment to refinery machinery. Sometimes these devices are old, large, or in hard-to-access places, and parts must be custom-built.

For about a century, U.S. Bronze Foundry & Machine has been a leading supplier of cast metal wear-, corrosion-, and heat-resistant products for challenging oil and gas drilling and processing applications.

What sets us apart is the ability to produce large cast products tailored to client specifications using static and centrifugal casting techniques. Our capabilities include:

Our facility houses a machine shop with advanced CNC equipment, enabling us to deliver finished castings with precise dimensions. This streamlines client supply chains by cutting out time-consuming secondary processing. We’re capable of machining workpieces with:

In oil and gas applications, degrading environments and process media are commonplace. They place components under extreme duress.

As a leading oil and gas castings manufacturer, we understand your challenges with equipment throughput, downtime, wear life, and efficiency. Our team partners with you to select the best material for your application. We work with a variety of metal alloys.

Other metal alloys can be used upon request. Contact us to discuss your needs further.

When receiving oil and gas casted metal parts from U.S. Bronze Foundry & Machine, you can rest easy. Components arrive on time and fit, form, and function as intended.

Every process performed follows stringent quality protocols. Rough parts are produced as quickly as two weeks, while finished pieces are manufactured as fast as eight weeks, depending on lead time and other factors.

Contact us to learn more about our oil and gas casted metal parts capabilities.