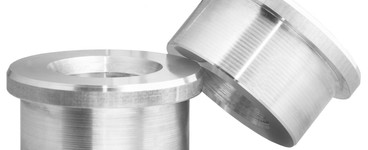

Straight Bushings

When it comes to heavy equipment and industrial machinery, degradation is commonplace.

Whether building a condominium tower, widening a highway, or erecting outdoor signage, the ability to safely fabricate materials and move heavy loads repeatedly is essential. Construction equipment malfunction or failure causes unwanted downtime and endangers vital personnel.

Enhance construction equipment performance with support from U.S. Bronze Foundry & Machine. We’re a leading manufacturer of custom cast metal products for demanding industries.

U.S. Bronze Foundry & Machine produces construction industry metal castings that stand up to wear, friction, and corrosion. As a result, equipment usability and longevity improve. Here are typical items we manufacture:

When it comes to heavy equipment and industrial machinery, degradation is commonplace.

As heavy materials pass through minerals processing equipment, components begin to wear.

Without nuts to hold things together, heavy equipment would fall apart.

Gears are toothed, mechanical transmission elements used to transfer motion and power between components.

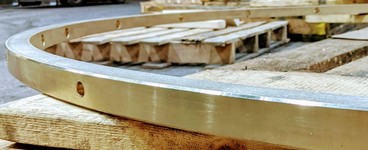

Cast rings are found all around us, from jet engines to military equipment.

Heavy equipment and machines are essential for completing industrial functions on time and within budget.

Heavy equipment success and failure sometimes comes down to the ability to withstand loads repeatedly.

Whether lifting substantial loads or crushing hard minerals, heavy machinery must tolerate extreme forces repeatedly.

In industrial applications, pumps and compressors are relied upon to power critical devices.

Unmitigated friction can bring any industrial application to a halt. Protect heavy equipment against wear with tapered bushings from U.S. Bronze Foundry & Machine.

Mining and materials-handling operators often must reduce raw material sizes to create something sellable.

When it comes to heavy machinery, unaddressed friction can be catastrophic.

The ability to withstand loads repeatedly is critical for heavy machinery. Boost equipment performance with flange bushings from U.S. Bronze Foundry & Machine.

Sometimes, being unbalanced better. Take your application to new performance levels with eccentric bushings from U.S. Bronze Foundry & Machine.

Every casting step is performed in-house under the guidance of a qualified engineering team. Our capabilities include:

Cast metal alloys are used in numerous construction applications because casting processes can create relatively complex shapes. Here are some examples:

Casting processes are adaptable for mass production. Large numbers of a specific casting can be produced quickly.

U.S. Bronze Foundry & Machine manufactures construction equipment parts castings of any size, but our specialty is large cast products tailored to client specifications. We utilize static and centrifugal casting techniques and have the following capabilities:

An onsite machine shop enables us to deliver finished castings with precise dimensions. As a result, the lead time associated with secondary processing is removed. The shop contains advanced CNC equipment capable of machining workpieces with:

Building sites are dusty, and work takes place no matter the conditions. It’s common for construction equipment to operate in wet environments, such as mud, rain, and snow. Components need to withstand these conditions.

As a top construction industry castings manufacturer, U.S. Bronze Foundry & Machine helps you identify the best metal alloys for your application. Those we use frequently include:

The construction industry plays an integral role in modern society. It’s responsible for the buildings where people live and work, not to mention the roads and bridges they use to get from one destination to the next. U.S. Bronze Foundry & Machine supports the industry by supplying high-quality cast metal parts.

A strict quality management system ensures every casted component meets applicable industry standards or client specifications. We can produce rough parts as quickly as two weeks and finished pieces as fast as eight weeks, depending on lead time and other factors.

Contact us to discuss your construction equipment parts casting needs further.